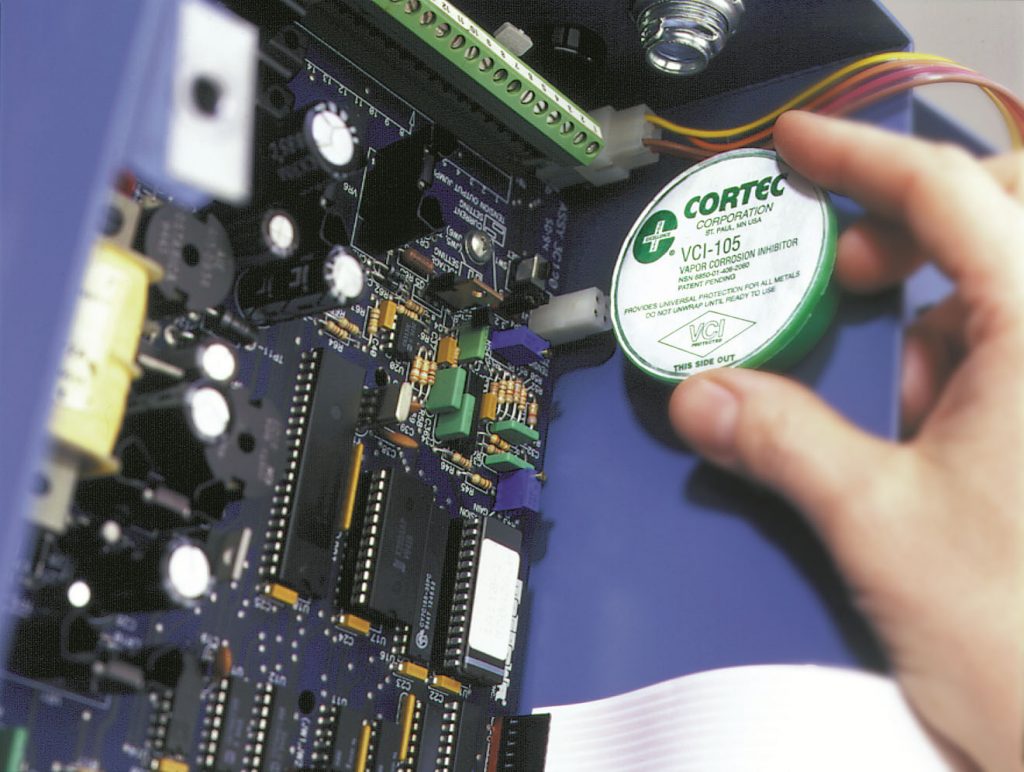

In addition to EnviroRinse®, Lake Engineering Solutions also offer a full range of Vapour phase Corrosion Inhibitors (VpCI®) corrosion protection solutions, conforming to international, government, military, and corporate specifications.

VpCI® solutions offer cost effective, high performance protection of parts, equipment, and structures for short or long-term requirements, in environments from in-plant preservation to aggressive marine environments.

Solutions range from coated papers, impregnated foams, extruded films, cushions, emitter devices, inserts, and custom designed solutions; ensuring ease of integration, simplicity of use, and uncompromised performance.

Vapor phase Corrosion Inhibitors (VpCI®) Technology

VCI is the generic term for “volatile corrosion inhibitor,” “vapor corrosion inhibitor,” or “Vapor phase Corrosion Inhibitor,” a proven technology that simplifies corrosion protection and is ideal for keeping enclosed void spaces (e.g. packages, equipment internals, or structural metal cavities) rust-free.

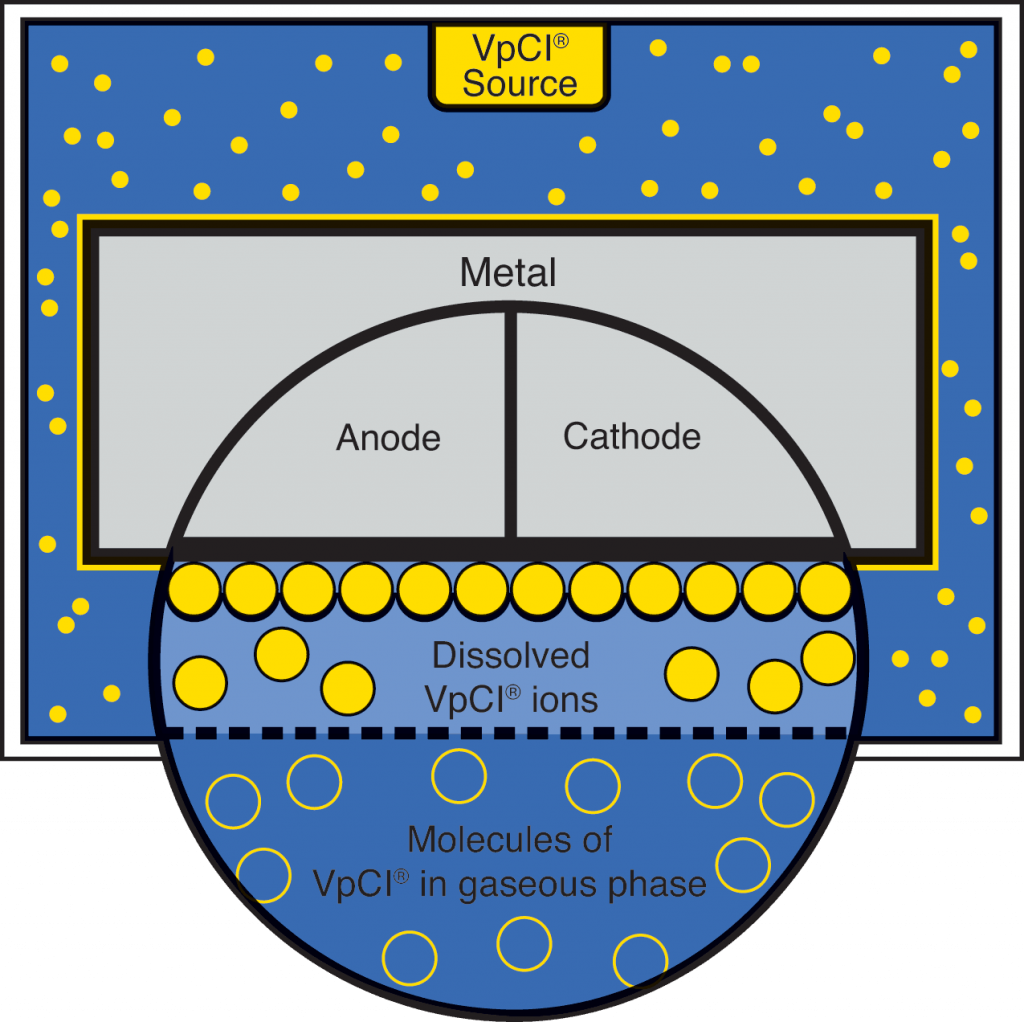

How Does VCI Work

VCI technology works to create a protective environment within each package or enclosure where it is applied. VCIs inside liquids, powders, or packaging materials travel through the air to form an invisible protective shield on metal surfaces in the enclosed space. This VCI shield does not alter metal properties. Instead, it blocks the ability of oxygen, moisture, and other corrosive elements to attack the metal surface and make it rust. After the metal part is taken out of the VCI packaging or enclosed space, the VCIs disperse, and the metal components, machinery, or products are ready for immediate use, no cleaning or degreasing required.

Advantages of VCI/VpCI® Technology

- Typically does not require the special removal of a coating or rust preventative

- Reduces labour time and hazardous waste disposal fees from having to clean off traditional petroleum-based rust preventatives

- Protects intricate equipment internals (e.g., pipes, boilers, valves) where it would be difficult if not impossible to apply a coating or liquid rust preventative

- VCIs do not require a constant source of electricity unlike dehumidification systems

- VCI technologies protect multiple metal types and work in multiple phases—liquid, vapour, and interface

Safety Benefits of VCI/VpCI® Technology

VCIs under the VpCI® brand name are generally safer to handle and less hazardous than other VCIs or those that rely heavily on nitrites. Many Lake Engineering Solutions products containing Vapor phase Corrosion Inhibitors are also recyclable or water-based and typically have a lower environmental impact than many harsher chemicals.

Effective Corrosion

Inhibitors

Stop corrosion by treating the root cause with the correct product choice under supervised application. Lake Engineering Solutions has practical experience of installations in different ambient conditions.

Health, Safety & Environment

Alleviate your concerns in the areas of health, safety, flammability, and pollution control.

Multimetal Protection

A full range of corrosion inhibitors are available to protect ferrous and non-ferrous metals, including formulations that protect combinations of metals.

Short-term and Long-term Protection

A range of products are available to provide temporary protection during in-plant processing, medium-term protection for shipment and storage, or extended protection for lay-up, mothballing, and field service.

For a variety of environmental conditions

Effectively protect your metals and products against corrosion from all aggressive atmospheres.

Protected parts are ready for use

The protective invisible layer deposited by VpCI® needs no removal, degreasing, scraping, cleaning, or further preparation. Your VpCI® protected components are ready for immediate use. If required, barrier coatings are easily removed with conventional cleaning methods.

Does not alter most material properties

In most cases, the invisible protective ionic layer of VpCI® does not alter important surface properties. This is even true for high precision electronic devices where conductivity, permittivity, and dimensional tolerances are crucial.